Our Process

On every project, we assemble a team of highly specialized engineers who bring a wealth of knowledge and experience with design, testing, sourcing, and production.

At every step of the process, we challenge ourselves to engineer a better solution—from a higher level of performance to a more cost-effective design. Our complete, in-house model delivers faster turn-around, greater efficiencies, and better solutions for our customers.

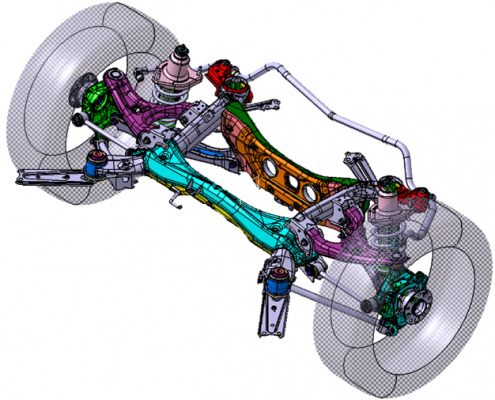

Design

Our design engineers excel within tight constraints. We understand how the parts we design fit into the big picture—and how the designs we develop affect the ride and handling of the vehicle.

We balance form and function, ensuring our designs fit precisely as intended and meet demanding performance and Noise/Vibration/Harshness targets. Our engineers are adept at synthesizing weight, performance, cost, and manufacturability, enabling us to deliver lightweight and highly effective designs time and time again. Throughout the entire process, our design engineers work closely with our CAE and prototyping groups to seek opportunities for improvement. We are agile problem solvers and quick to adapt to new challenges and requirements from our customers.

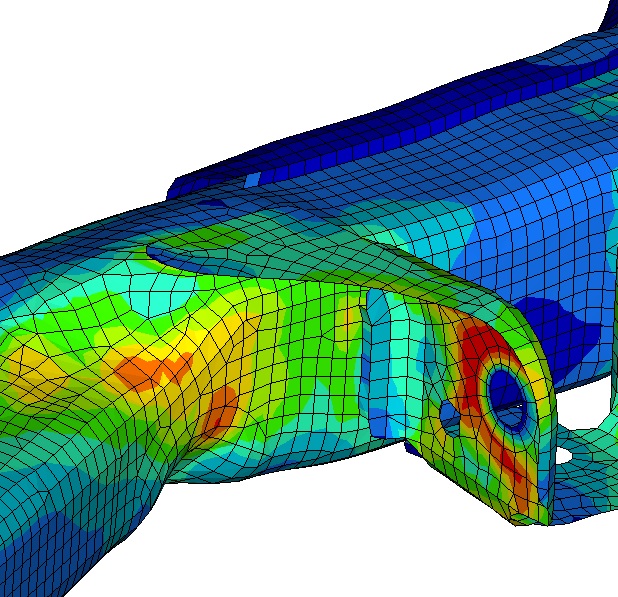

CAE

Our CAE engineers are always looking ahead. We constantly research and evaluate new materials and technologies to stay on the leading edge of innovation. We are always focused on optimization, looking past results to develop solutions that enhance performance.

Our CAE engineers also simulate real-world conditions on the parts we design, expertly analyzing nonlinear and linear durability, dynamic/static stiffness, mobility requirements, Noise/Vibration/Harshness, welding, and e-coat. With a solid baseline of excellent correlation results, our CAE team can quickly narrow down potential issues or identify ways to improve the design, resulting in less rework, less cost, and a faster response for our customers.

Our advanced capabilities, extensive material expertise, and proven success with simulations also enables us to help customers test new ideas before design is underway.

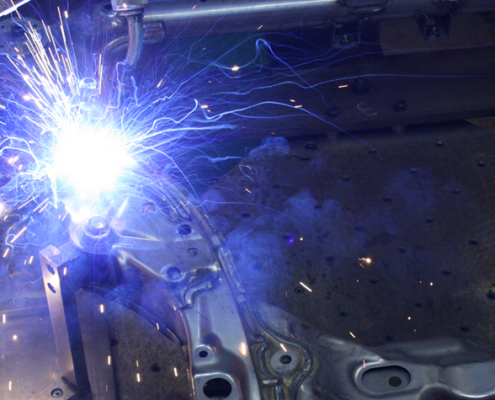

Prototype

Our proto group brings structure to ideas. We draw from our expansive knowledge of advanced manufacturing techniques and materials procurement, and from our pool of trusted in-house, local, and overseas suppliers, to ensure that our customers are getting the best value in terms of manufacturability and cost.

From material selection to welding quality, our prototypes are of the highest quality and built to precision, bolstered by our resourcefulness, our years of experience, and our manufacturing know-how. Our in-house capability facilitates communication between our design and testing departments, streamlining the proto process—which benefits our customers when new materials, processes, or technologies are involved.

Test

Our test group puts our designs through their paces, ensuring our parts perform as intended. We physically test strength, fatigue, and durability using single-axis and multi-axis testing. Our multi-axis machine allows testing in six degrees of freedom, running our designs through such real-world demands as wheel torque, braking torque, wheel movement, and more. Our state-of-the-art corrosion chamber also allows us to conduct in-house accelerated environmental testing and cyclic corrosion.

Our testing engineers don’t just test for performance; they are also skilled with root-cause analysis and are adaptable at meeting different testing requirements. At the end of the day, they ensure that all designs we deliver exceed the level of quality expected by our customers.